DENVER (AP) — As People wrestle beneath backbreaking rental costs, builders are turning to modern methods to churn out extra housing, from 3D printing to assembling houses in an indoor manufacturing facility to utilizing hemp — sure, the marijuana cousin — to make constructing blocks for partitions.

It’s a response to the nation’s shortfall of hundreds of thousands of houses that has led to skyrocketing costs, plunging hundreds of thousands into poverty.

“There’s not sufficient houses to buy and there’s not sufficient locations to hire. Interval,” mentioned Adrianne Todman, the performing secretary of the U.S. Division of Housing and City Improvement beneath former President Joe Biden.

One option to shortly construct extra is embrace some of these improvements, Todman mentioned. “I can solely think about what our housing scenario can be like now if we might have decided to be extra aggressive in adopting one of these housing” many years in the past.

So what are these new methods of constructing houses? And might they assist scale back the price of new housing, resulting in decrease rents?

Manufacturing unit-built housing put collectively in every week

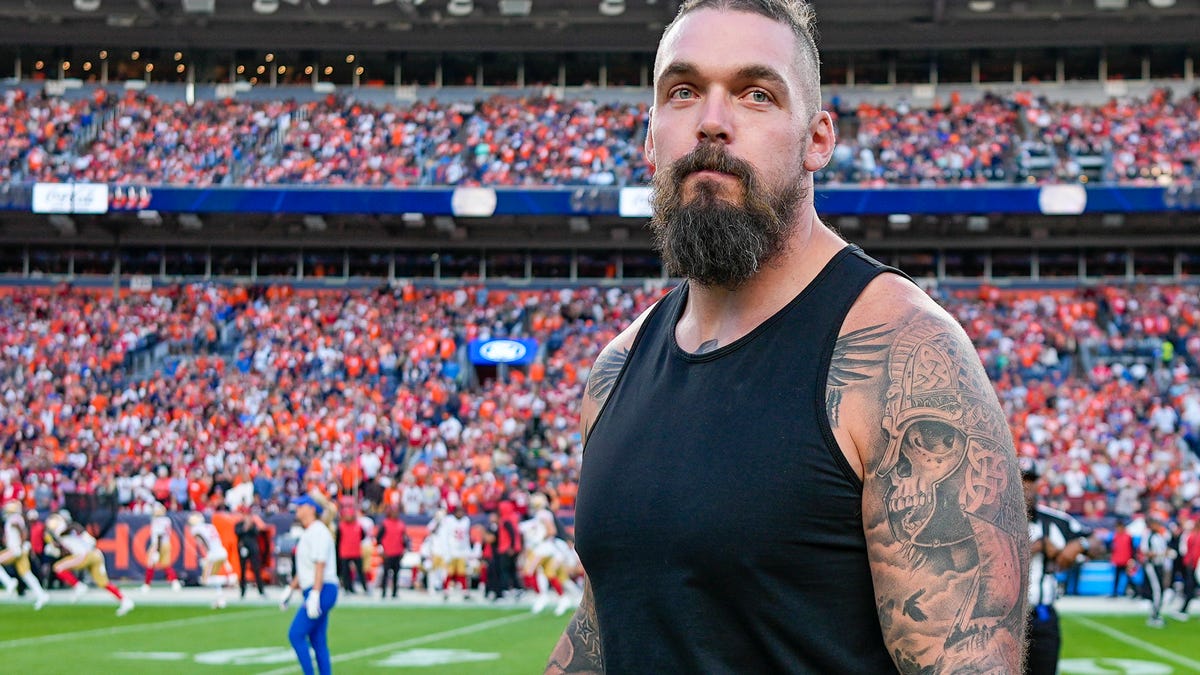

In a cavernous, metallic corridor, Eric Schaefer stood in entrance of an extended row of modular houses that moved by way of the plant, just like a automotive on an meeting line.

At a sequence of stations, employees lay flooring, erected framing, added roofs and screwed on drywall. Every thing from electrical wiring to plumbing to kitchen counter tops have been in place earlier than the houses have been shrink-wrapped and able to be shipped.

The enterprise within the Colorado Rocky Mountains, Fading West, has pumped out greater than 500 houses in its simply over three years of operation, every taking simply 5 to seven days to construct, even within the coldest winter months, Schaefer mentioned.

As soon as assembled within the plant, the slender townhouse-style houses with white trim, balconies and entrance porches, are about 90% finished. At their ultimate vacation spot they’re move-in prepared inside six weeks, Schaefer mentioned.

The corporate works with cities, counties and housing nonprofits to assist deal with the scarcity of inexpensive houses, largely for employees who’ve been squeezed out by sky-high costs in ritzy mountain cities.

That features Eagle, Colo., not removed from the Vail ski resort, the place Fading West labored with Habitat for Humanity to put in modular houses at inexpensive rents for lecturers and different college district staff. The houses are typically on the smaller facet, however might be multifamily or single household.

“You may construct quicker. The quicker you construct — even at a top quality — means the decrease the value,” Schaefer mentioned. “We see this as one of many items to the puzzle in serving to clear up the inexpensive housing disaster.”

There’s a hefty upfront price to construct the manufacturing facility, and a part of the problem is an absence of state and federal funding, he mentioned. A patchwork of constructing codes governing how a construction might be constructed additionally makes it tough, requiring adjustments to the development relying in town or county it’s being despatched to.

Manufactured housing is just like modular housing, however the models are constructed on a chassis — like a trailer — they usually aren’t topic to the identical native constructing codes. That’s a part of the explanation they’re used extra broadly throughout the U.S.

Roughly 100,000 manufactured houses have been shipped to states in 2024, up from some 60,000 a decade earlier, in keeping with Census Bureau knowledge. Estimates of modular houses constructed yearly typically put them beneath 20,000.

3D printing is modern however nonetheless ‘an extended sport’

Sure, there’s expertise to 3D print houses.

A pc-controlled robotic arm outfitted with a hose and nozzle strikes forwards and backwards, oozing traces of concrete, one on prime of the opposite, because it builds up the wall of a house. It may well go comparatively shortly and type curved partitions in contrast to concrete blocks.

Grant Hamel, CEO and co-founder of VeroTouch, stood inside one of many houses his firm constructed, the wall behind him made out of rolling layers of concrete, distinct to a 3D printer. The expertise might ultimately scale back labor prices and the time it takes to construct an abode, however is farther off than manufactured or modular strategies from making a dent within the housing disaster.

It’s “an extended sport, to start out chipping away at these costs at each step of the development course of,” Hamel mentioned.

The 3D printers are costly, and so are the engineers and different expert staff wanted to run them, mentioned Ali Memari, director of the Pennsylvania Housing Analysis Heart, whose work has partly centered on 3D printing. It’s additionally not acknowledged by worldwide constructing codes, which places up extra purple tape.

The expertise can also be usually restricted to single-story constructions, until conventional constructing strategies are used as nicely, Memari mentioned

It’s “a expertise at its starting, it has room to develop, particularly when it’s acknowledged in code,” Memari mentioned. “The challenges that I discussed exist, they usually must be addressed by the analysis neighborhood.”

A hemp-and-lime combination referred to as hempcrete has ‘a shiny future’

Hemp — the plant associated to marijuana — is getting used increasingly within the building of partitions.

The hemp is combined with different supplies, most significantly the mineral lime, forming “hempcrete,” a pure insulation that’s mold- and fire-resistant and might act as outer wall, insulation and internal wall.

Hempcrete nonetheless requires wooden studs to border the partitions, but it surely replaces three wall-building elements with only one, mentioned Memari, additionally a professor at Penn State College’s Division of Civil and Environmental Engineering. Memari is now serving to oversee analysis into making hempcrete that doesn’t want the wooden studs.

As a lot as 1,000,000 hemp vegetation for use for hempcrete can develop on one acre in a matter of months versus timber, which might take years or many years to develop.

The plant is a part of the hashish household however has far much less of the psychoactive part, THC, present in marijuana. In 2018, Congress legalized the manufacturing of sure varieties of hemp. Final yr, the Worldwide Code Council, which develops worldwide constructing codes utilized by all 50 states, adopted hempcrete as an insulation.

Confusion over the legality of rising hemp and the value tag of the machine required to course of the plant, referred to as a decorticator, are obstacles to hempcrete changing into extra widespread in housing building, Memari mentioned.

Nonetheless, he mentioned, “hempcrete has a shiny future.”

Related Press video journalist Thomas Peipert contributed to this report from Buena Vista, Colorado.